Gasifier Systems

EARTHCARE offers a Gasification Processing System to produce ECOCHAR. Our Gasifier System processes all types of manures as well as by-products from animal and food processing plants and all types of vegetation such as wood, switch grass, cord fodder, etc. to produce various grades of Biochar (from wood & vegetation by-products) and ECOCHAR (from manure, municipal sludge and by-products from food & animal processing facilities). ECOCHAR is the carbon-rich product obtained when biomass is heated in a closed container, in either an oxygen-starved or oxygen-free environment.

Gasification produces a material that contains the mineral ash from the feedstock as well as the fixed carbon – which will be in the form of a carbon char. The carbon in this char is transformed into a very absorbent material that has charged particles which attract nutrients and moisture. We include a BIO-FILTER in our Gas Exhaust System that greatly reduces the emissions to a very low PPM and eliminates the odor of any exhaust from the gases.

IMPACT AIR QUALITY AND OVERALL ENVIRONMENT

Biomass materials contain carbon in two forms – fixed carbon and volatile matter. The carbon in the volatile matter is reacted in the process, while the fixed carbon is left behind in the ECOCHAR. Due to the high temperatures and retention time, ECOCHAR is free from pathogens, E-coli, growth hormones, and residues from medications. We are presently testing the elimination of PFOS in the processing water treatment sludge in our system.

The resulting product has a multitude of applications due to the characteristics of the carbon along with the nutrients in the char – possible uses include soil amendment, heavy metal remediation, animal feed supplement, water purification, eliminate odor, reduce ammonia & moisture in poultry houses and many others.

Purified water and a healthier soil produce healthier plants and healthier nutrition for human consumption. This also enhances the health of all human beings as well as all animals and birds.

OVERVIEW

- Gasification is a thermal process, reacting carbon-based fuels in an oxygen starved environment.

- The syngas produced in the gasifier is then combusted in a thermal oxidizer.

- The product of gasification is heat and biochar.

- Fixed bed gasifier. Material is conveyed through the gasifier with augers.

- Controlled amount of air introduced to provide oxygen starved environment Gas produced is primarily CO.

- Gasifier temperature typically ranges from 1000 to 1500 degrees F.

- Gas is pulled from the gasifier through the oxidizer. Additional, controlled volume of air is added to combust gases and convert CO to CO2.

- Oxidizer exit temperature typically ranges from 1600 to 2000 degrees F.

- Feed rates and biochar removal rates are controlled through Variable Frequency Drives to control throughput, energy output, and biochar quality.

- Control of air fans also provides throughput and energy output control, as well as controlling particulate carryover into the emissions stream.

ECOCHAR

- Ecochar is the carbon-rich product obtained when biomass is heated in a closed container, in either an oxygen-starved or oxygen-free environment.

- Gasification produces a material that contains the mineral ash from the feedstock as well as the fixed carbon – which will be in the form of a carbon char.

- The carbon in this char is transformed into a very absorbent material that has charged particles which attract nutrients and moisture.

- Biomass materials contain carbon in two forms – fixed carbon and volatile matter. The carbon in the volatile matter is reacted in the process, while the fixed carbon is left behind in the ecochar.

- Due to the high temperatures and retention time, Ecochar is free from pathogens, E-coli, growth hormones, and residues from medications.

- The resulting product has a multitude of applications due to the characteristics of the carbon along with the nutrients in the char – possible uses include soil amendment, heavy metal remediation, animal feed supplement, and many others.

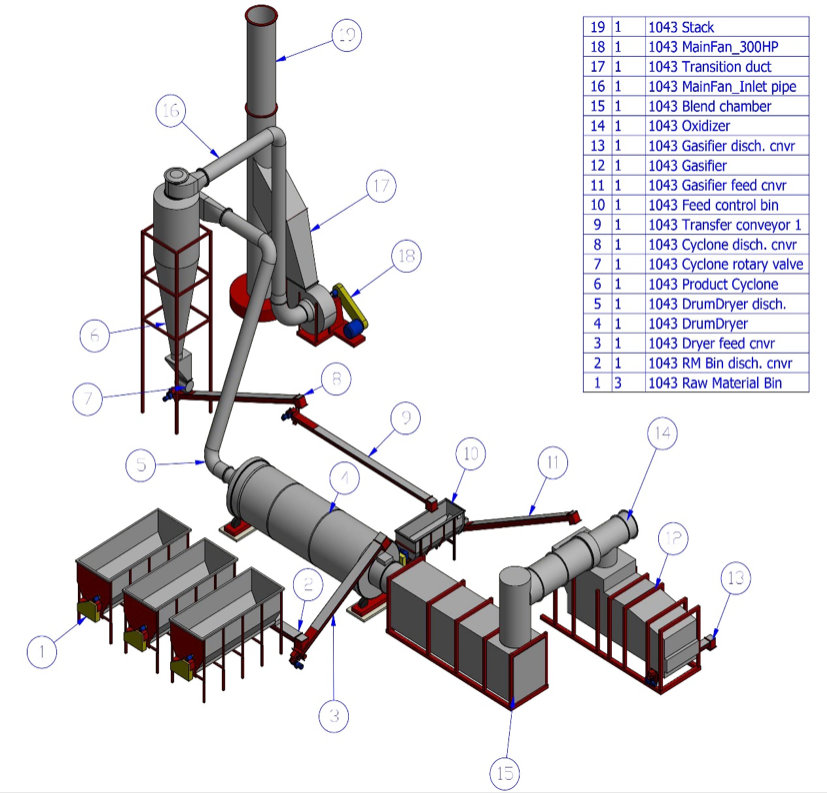

EARTHCARE GASIFIER

Benefits of Gasification

- Meets regulatory requirements with an alternative solution

- Converts waste material into a revenue stream

- Select best use(s) for energy —heat, chilling, steam, or electricity, with the option of varying the use depending on demand

- Eliminates or reduces costs now associated with waste disposal

- Halts the release of non-beneficial nutrients to waterways as a result of runoff from farm fields and storage piles

- Odors are destroyed in the gasification process

- Creates multiple revenue streams — EcoChar, animal bedding, etc.

- Easy to operate — designed to operate unattended and requires little maintenance

- Reduces carbon footprint

- Opportunity for revenue from tipping fees

- When environmental concerns are eliminated, business may be allowed to expand without increased land requirements for permitting

- Final product (EcoChar) is pathogen-free, greatly reduced in volume, and has value in a variety of applications

- Off-site monitoring available

Earthcare addresses waste disposal and facility energy needs, allowing business owners to concentrate on their core business expertise. Earthcare's gasification systems can produce heat, steam and/or electricity as desired, as well as Ecochar (our trademarked biochar product), and are designed to fit the host site's needs. Depending on the application, a portion of the thermal energy may also be used to dry moisture-laden products (waste grain, vegetable residue, high-moisture manures, etc.), making them easier and less costly to transport or use for fuel. Our gasifiers are extremely versatile and are able to operate using a variety of different fuels, while remaining a carbon negative solution for your business.

Maximizing the value of your waste stream while improving the environment